What is DHF Bi-met™, Essentially, DHF’s Bi-met technology is the fusing of thermal spray to boiler pipes using Induction Heating (IH) to form a self-fluxing alloy coating. Our process has achieved what has been deemed technically impossible in the maintenance of boilers and other large equipment parts as listed below.

- 1) High consistency and reproducibility in the quality of lining formation;

- 2) High flexibility (adaptability) in design and application enabled by fusing and bending processes through the use of IH; and

- 3) Wide variety of lining options depending on intended usage.

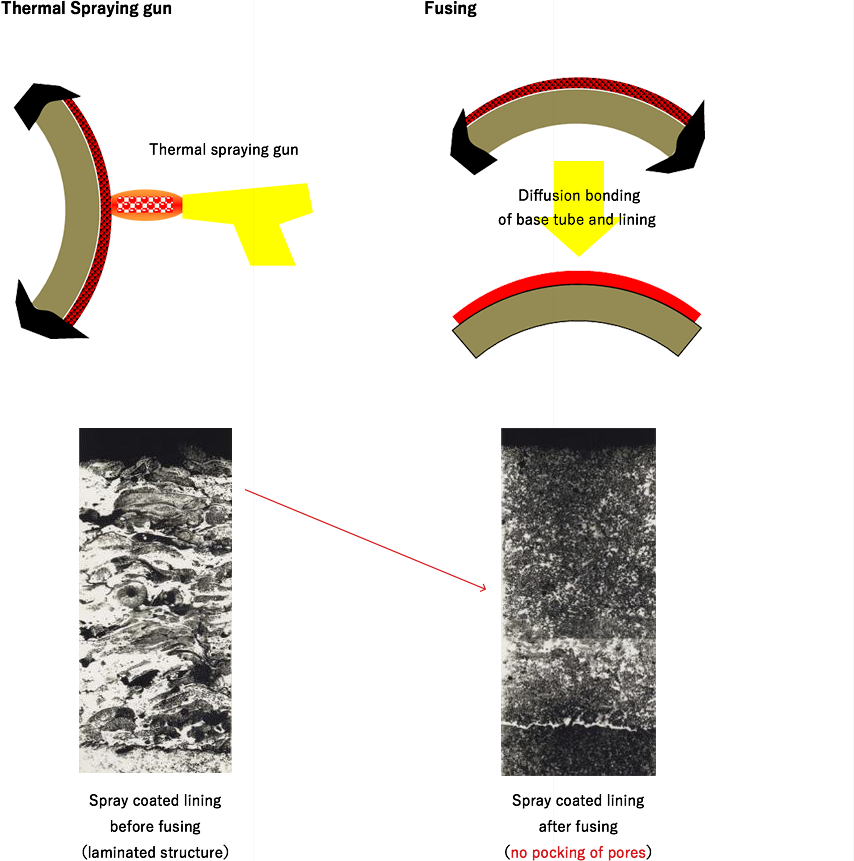

Fusing Process

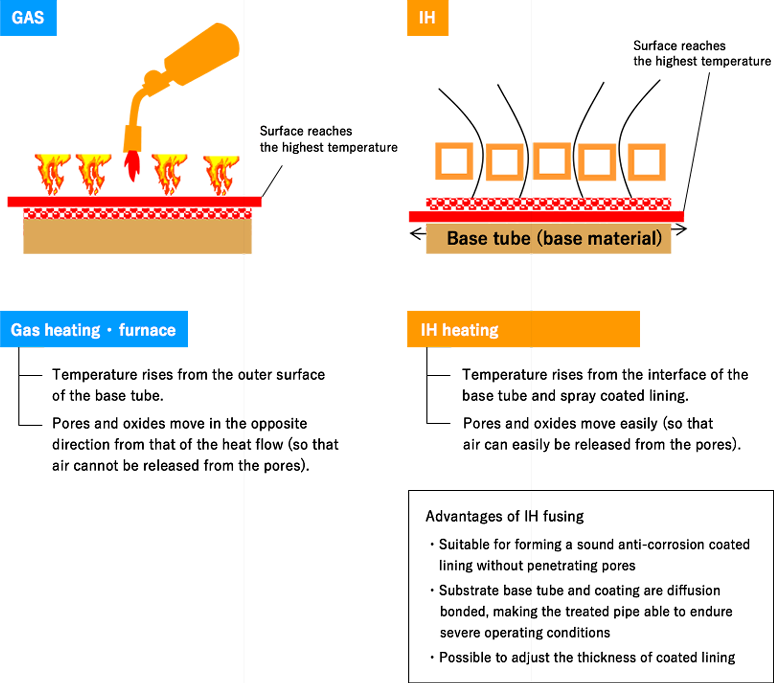

The fusing process is carried out by using either of two heating methods: gas or high frequency induction heating (IH).

Gas fusing

IH fusing

Quality of Coated lining

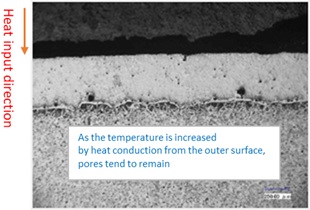

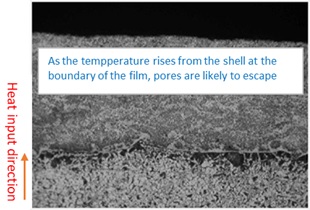

Pores or slag easily remain.

Pores or slag are removed to form a sound coated lining.

Adhesion

Can be irregular and inconsistent

Uniform diffusion bonding results in strong adhesion

(Fig. 2)

Lining thickness

Not suitable for thick linings

(up to only about 2 mm)

Possible to form thick linings

(2 mm and over)

Effect on base material

Large negative effect due to long duration of heat treatment

Small effect due to controlled, short duration of heat treatment

Consistency of quality

Not quite consistent due to manual operation by workers

Consistent due to mechanically controlled operation

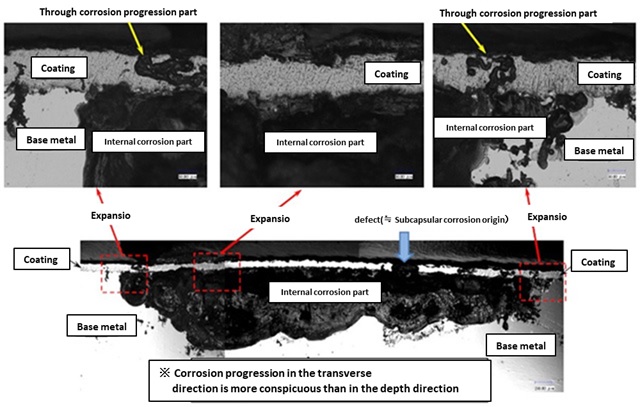

Condition of water –wall panel treated with standard onsite thermal spray process – (Note pores and corrosion of base material)

Differences in coated linings using different fusing methods

Difference between DHF Bi-met and other processing methods

HVOF thermal spraying

Build-up welding

DHF Bi-met

Lining material

Ni-Cr

Inconel 625

Ni-based SF alloy

Dilution

N/A

Applicable Fe: 10 - 20%

N/A

Lining thickness

Approx. 0.2 mm

>1.5mm

0.5 mm - 2.0 mm in practical applications

Effect of heat on panel

Minimal

Yes

Minimal

Thermal strain

Minimal

Yes

Minimal

As anti-corrosion measure

Not suitable

Suitable

Suitable

As anti-wear measure

Suitable

Not suitable

Suitable

Adhesion

70Mpa

450Mpa

400Mpa

Lining hardness(HRC)

>45

<40

>55

Surface condition

Slightly uneven

Uneven

Smooth and even

Control over lining thickness

Easy

Rather difficult

Easy

Flexibility in design

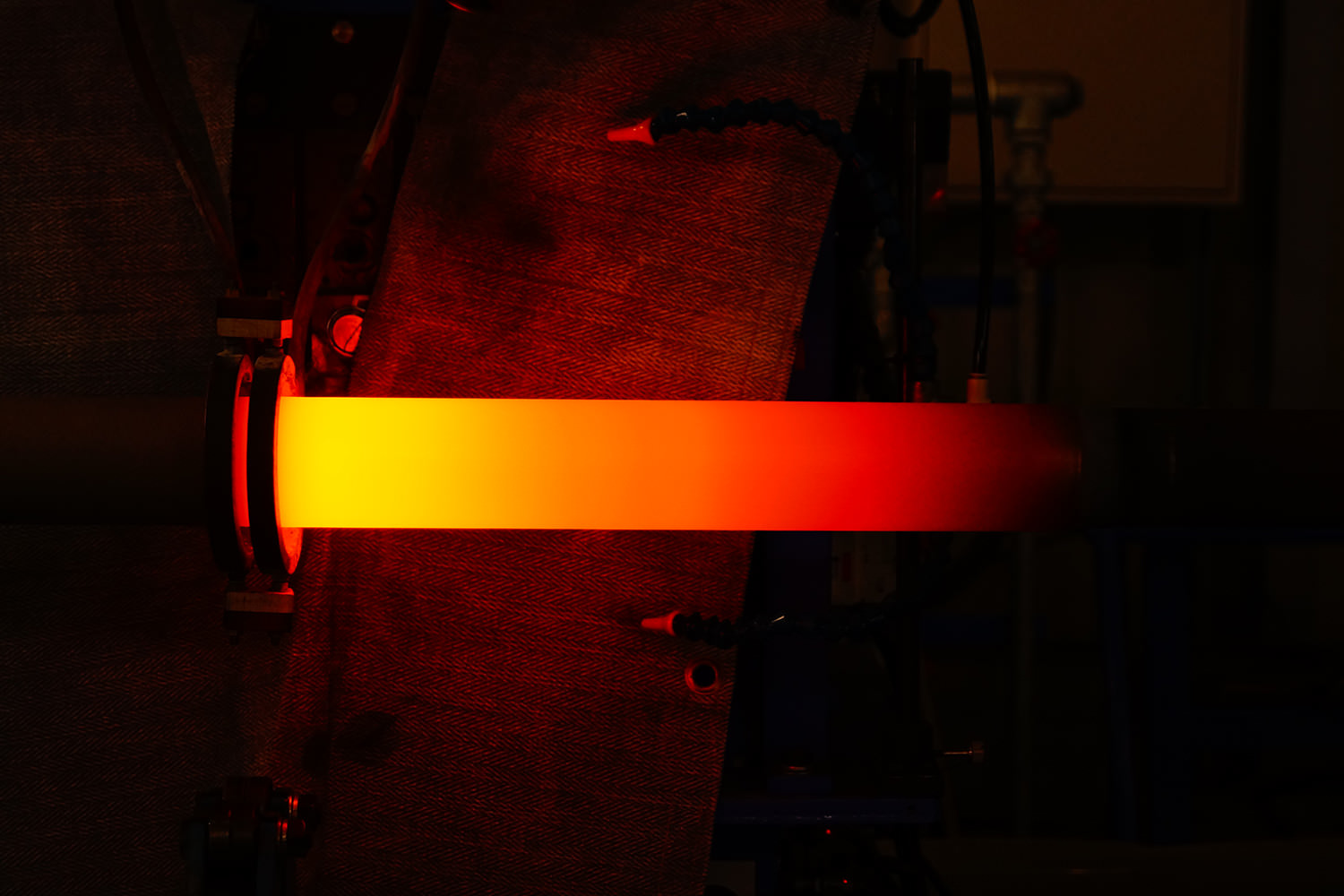

DHF Bi-met™ products can also be subject to pipe or panel bending processes conducted at the same time as the high frequency IH re-melting (fusing) process after thermal spraying.

The products allow for higher flexibility in design as they can be applied to parts of various shapes and sizes as shown in the photos below.