CORE TECHNOLOGYDHF's Core Technologies

There are many DHF technologies that could be called "core". The technologies that we have developed and continue to develop are being put to use throughout the world in all kinds of fields. Other companies cannot compete with us in terms of reliability and durability.

Heating Technology & Future Needs

Electromagnetic Wave Applications

We provide heating solutions for our customers' future needs, including high-frequency induction heating, microwave heating, laser heating, and numerous other heating technologies.

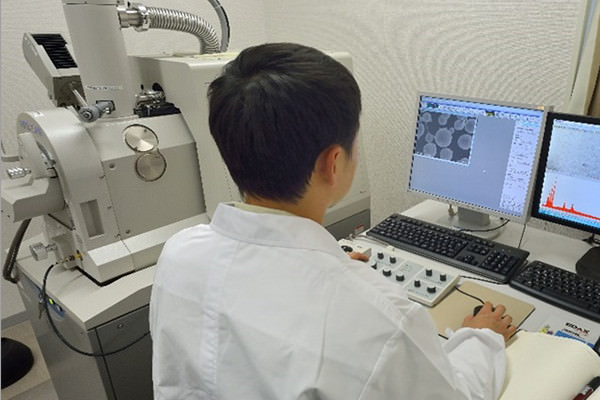

Processing Technology & High Level Technology

Shaping/Moulding Technologies

Shaping/mould technologies, combining both heating and analytical technologies are used not just to bend pipes and shape rebar, but also to make a variety of other processing methods possible on ordinary metals as well as non-ferrous metals.

New Materials Technology & New Fields

New Materials

With carbon fiber and other materials, now-a-days being widely used in many fields of advanced technology, we aim to open up the future by pioneering new processes and uses for these materials.

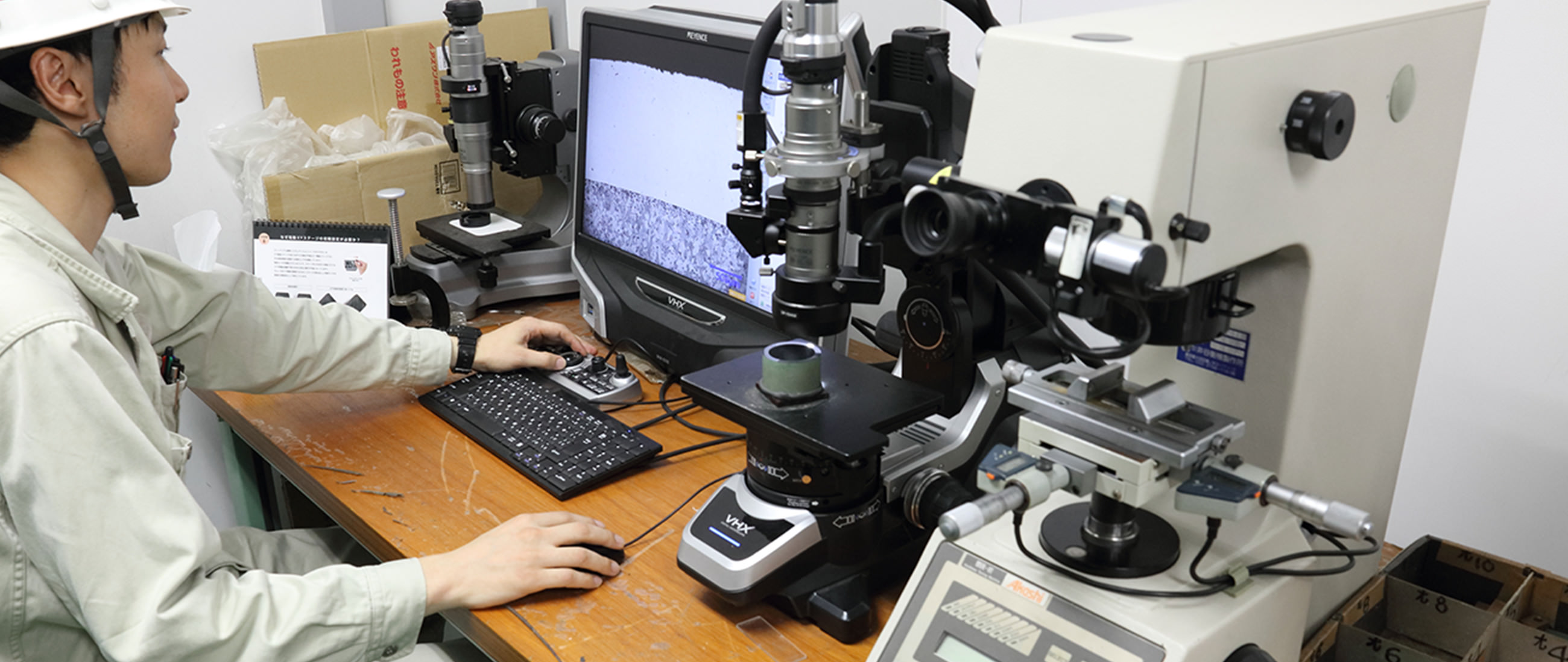

Coating Technology & Protection

Surface Modification Technologies & Anti-Rust/Anti-Corrosion Technologies

DHF Technology makes kind of coatings a reality, making use of a wide array of materials from resing.

We strive to satisfy the demands of our many clients who want superior coating technology to prevent wear, rust, corrosion, etc. of their plants and equipment.

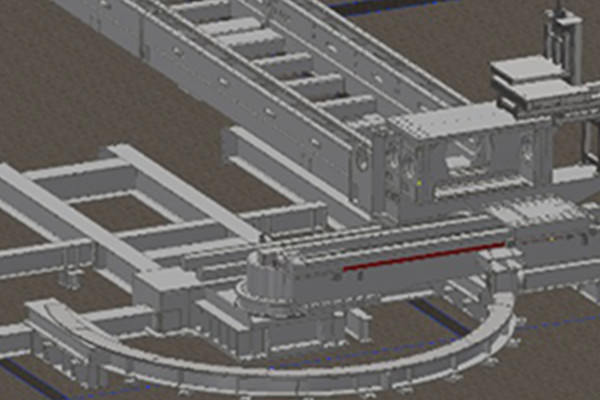

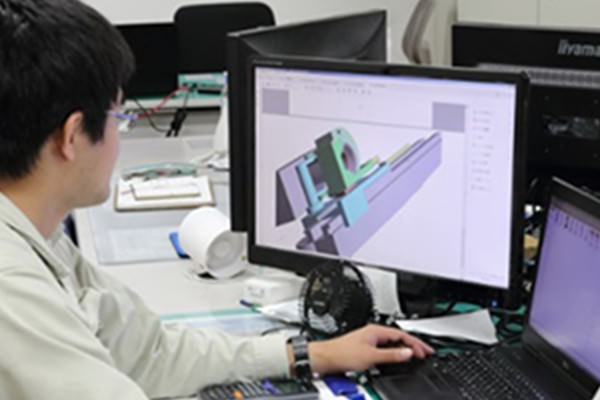

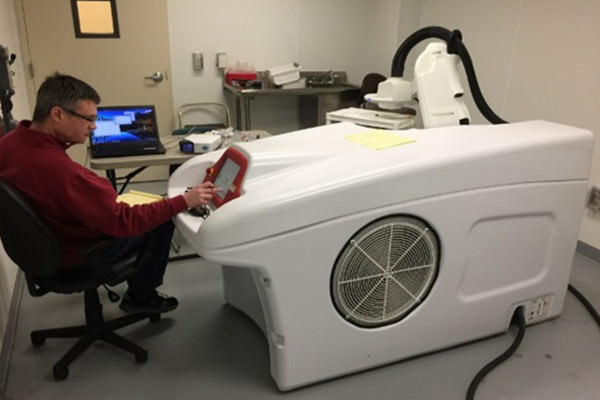

Design・Manufacturing Technology

Equipment Design Technology

We design and produce equipment that can analyze past experiences and data and help predict future developments.

For questions about our technologies and their development

Click hereINDUSTRIAL TECHNOLOGYFlow of Manufacturing Devices

We create in-house the technology used to design DHF products, then fabricate, install,and conduct maintenance on the products. In this respect, we continuously strive with our support network to improve product quality and meet delivery deadlines.

Rooted in these experiences, we design and manufacture devices that meet customer needs, and offer those devices to customers in a simple and efficient format.

- Inquiries and requests from customers

- Feasibility study, test to confirm feasibility, confirm analysis

- Proposed equipment and equipment options for job, confirmation of specifications, and presentation of proposal and options to customers

- Equipment design and design review

- Customer's approval of specifications (estimate of quoted specifications and production specifications)

- Design of equipment and design review

- Manufacture and devices process management

- Installation/assembly and inspection

- Testing, Adjustments based on trial run, on-site check, and delivery

- Regular maintenance (facility diagnostics) and follow up to further questions or inquiries